For those with an interest in the area of hydraulics, this tutorial provides an in-depth guide on how to efficiently wrap a hydraulic hose, specifically from sizes -4 to -12. This method is considered a swift process and ensures adequate protection and longevity of the hose.

The first step is to properly assess the hose size. This is vital as hoses come in different sizes, with each one requiring a specific kind of wrap application. Hydraulic hoses from -4 to -12 are the focus of this tutorial.

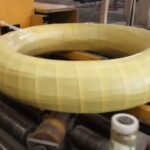

Using a hose wrapping machine can greatly simplify this process. This machine is specially engineered to neatly and tightly wrap hosing of varying sizes. You must position the hose correctly within the device to ensure precise wrapping.

Next, place the wrap material around the hose before activating the machine. As the wrapping process commences, ensure the hose remains immobile inside the machine for accurate wrap placement. While the machine is operating, constantly monitor to prevent any unwanted snags or overlaps.

Once the wrapping process is complete, remove the hose from the machine with care, avoid unwrapping, and ensure that the wrap has been securely placed around. This stage marks the conclusion of the hose wrapping process.

To garner further insights into this process, feel free to delve deeper into our coil packing solution. This resource is industry-leading and provides the most professional solutions available to date. It’s a wonderful aid for those looking to elevate their understanding of hose wrapping methods. With the right knowledge and tools, you too can perfect the quick process of wrapping a hydraulic hose from -4 to -12. Coil Packing Machine

Easy Step-by-Step Hose Wrap Tutorial

#Hose #Wrap #Tutorial